Model Rocket Avionics

A full-featured avionics suit developed for high-power model rockets

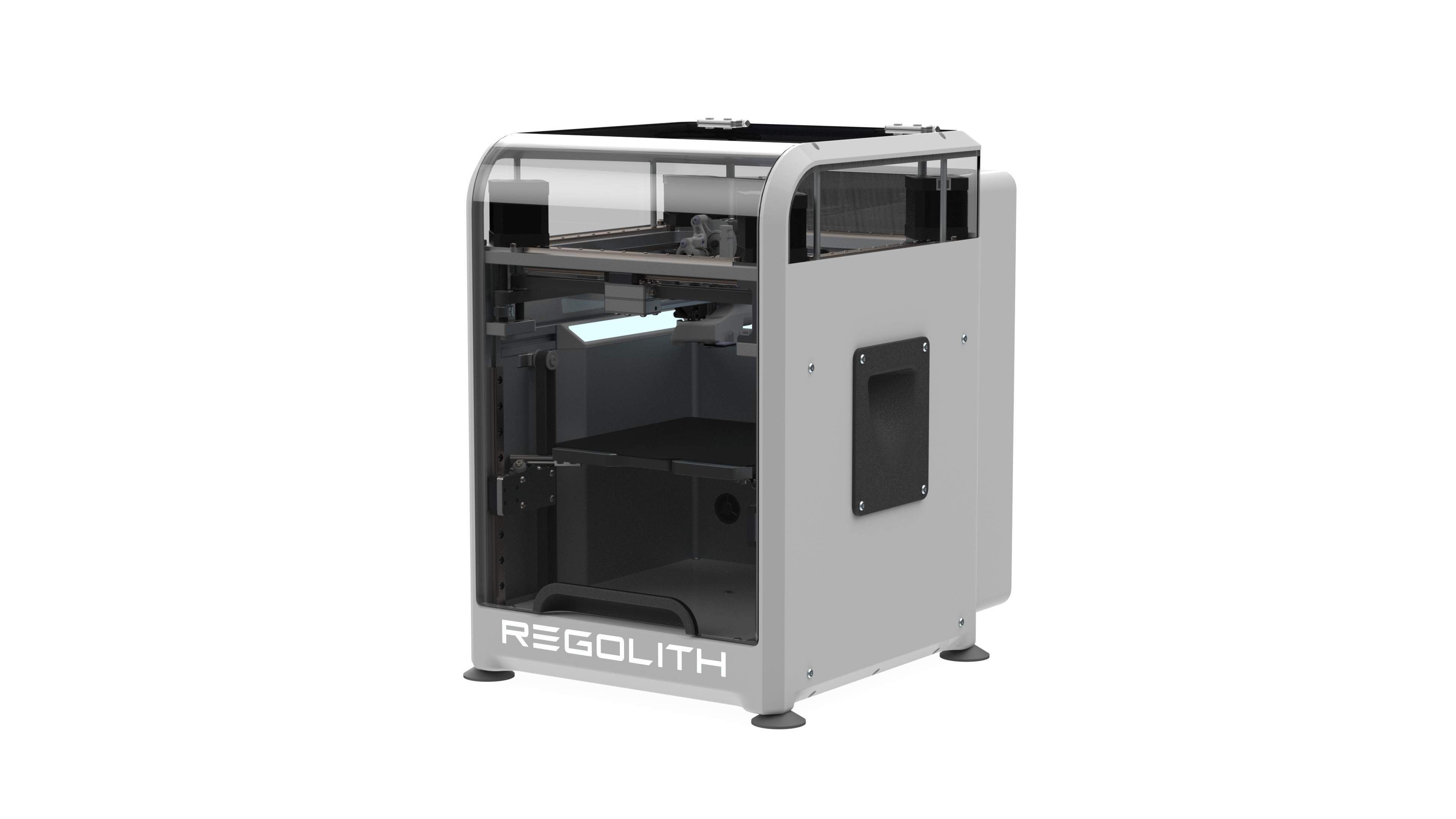

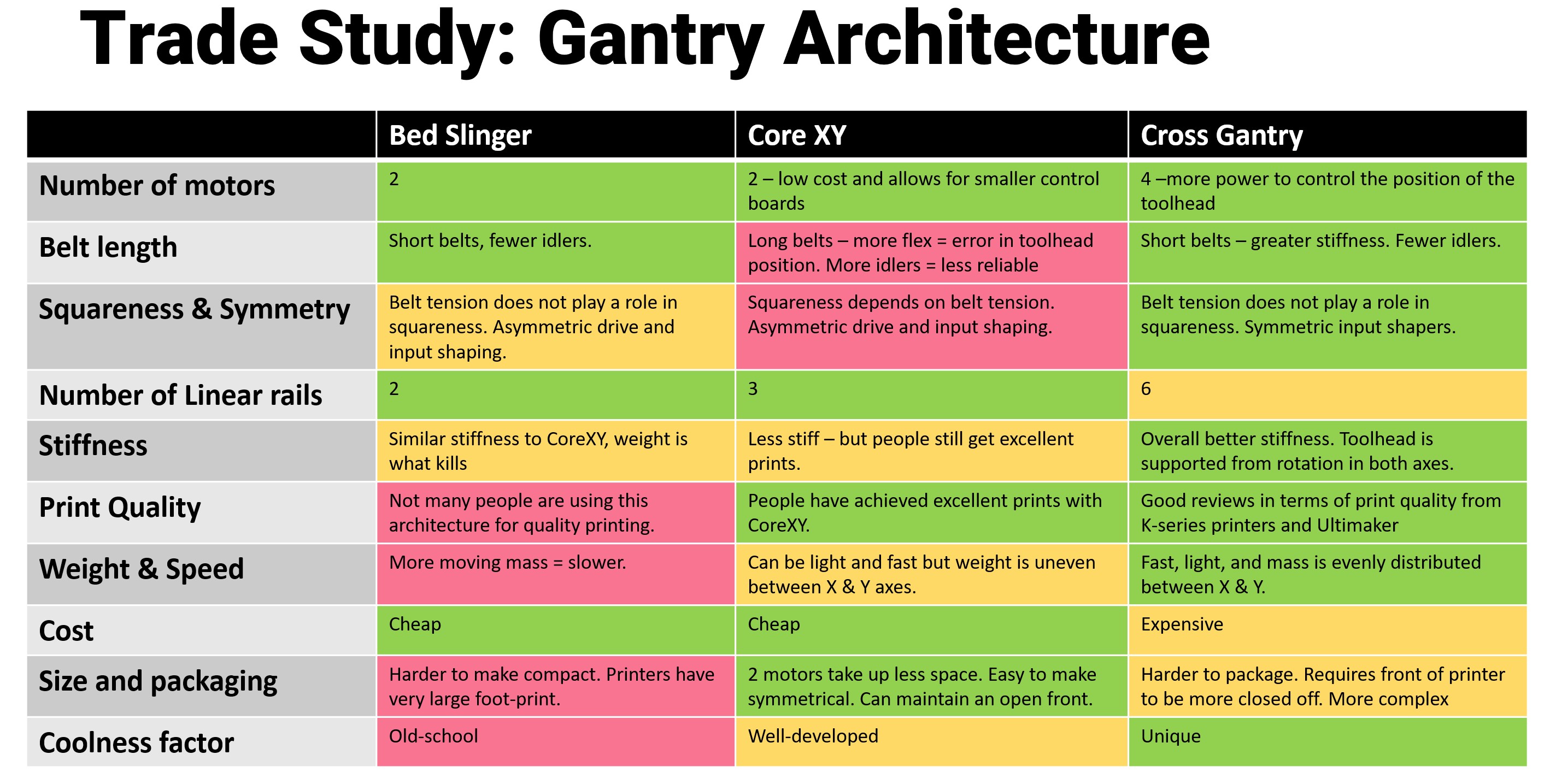

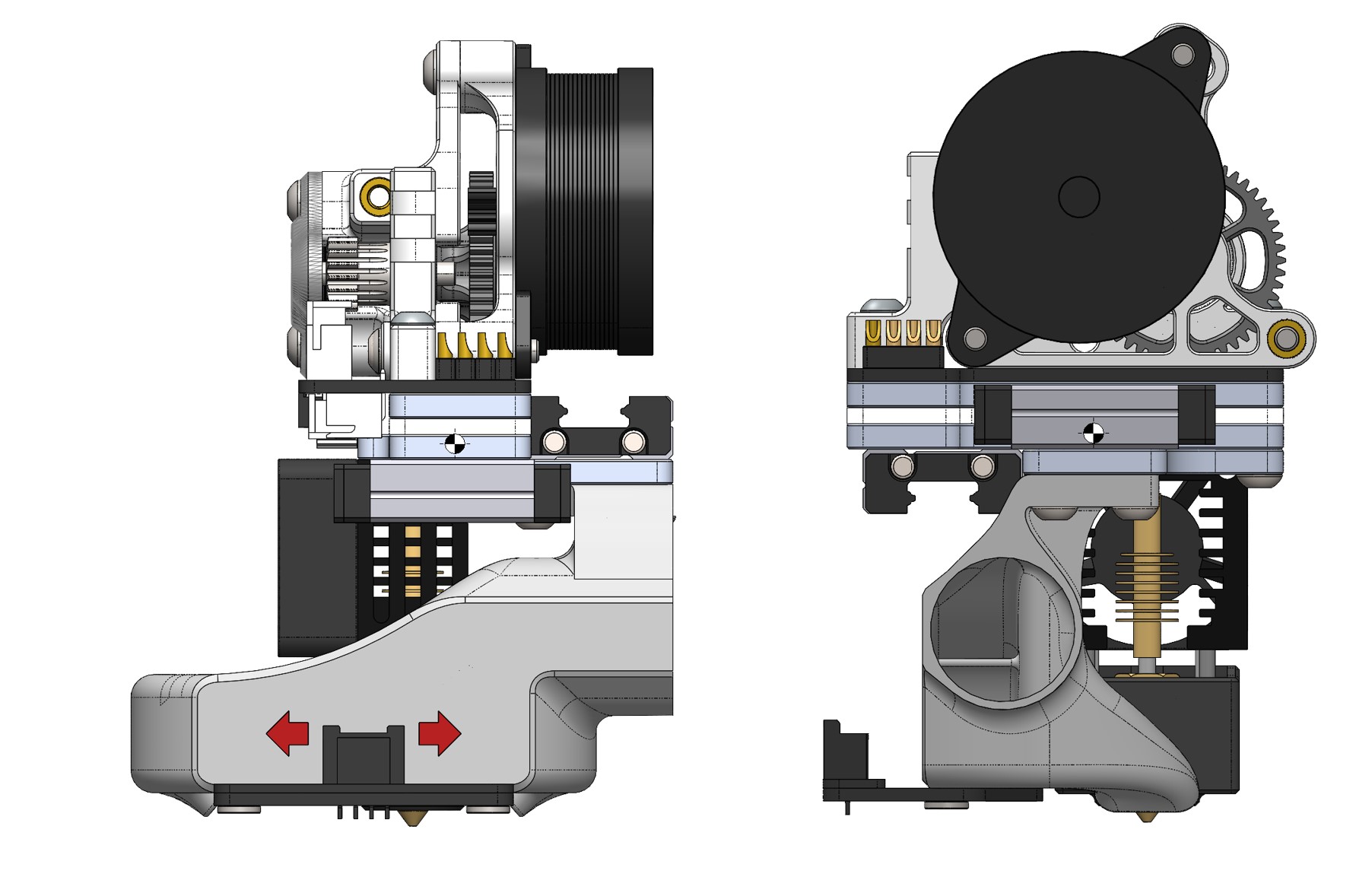

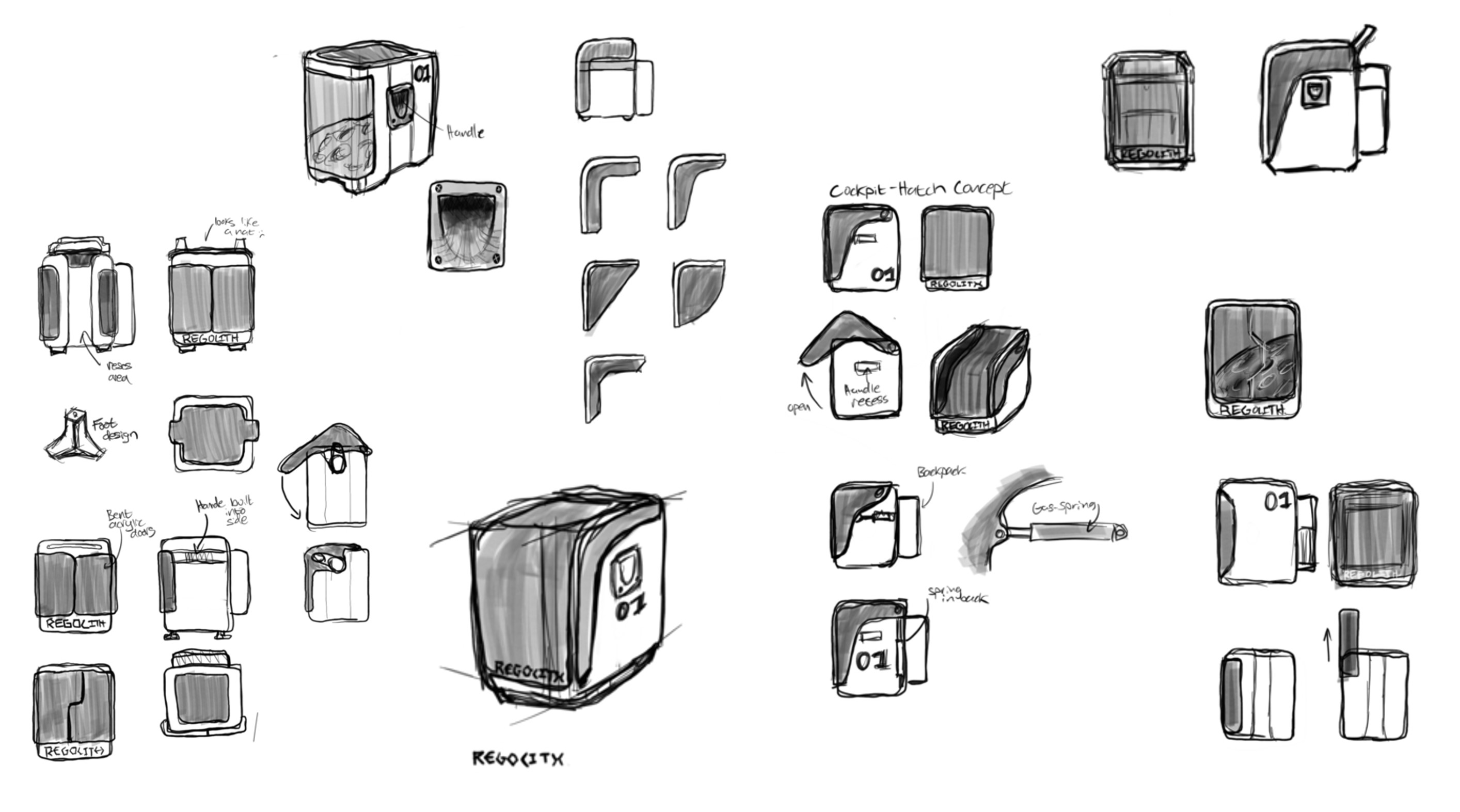

A performance FDM printer with cutting-edge kinematics.

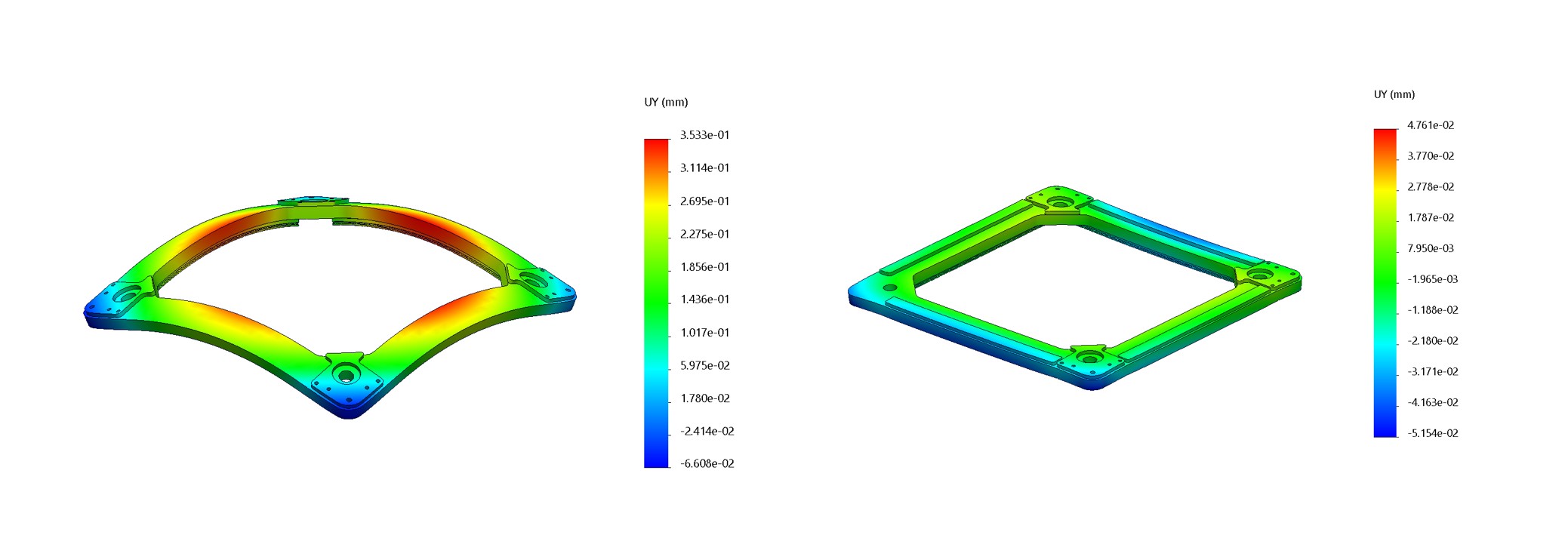

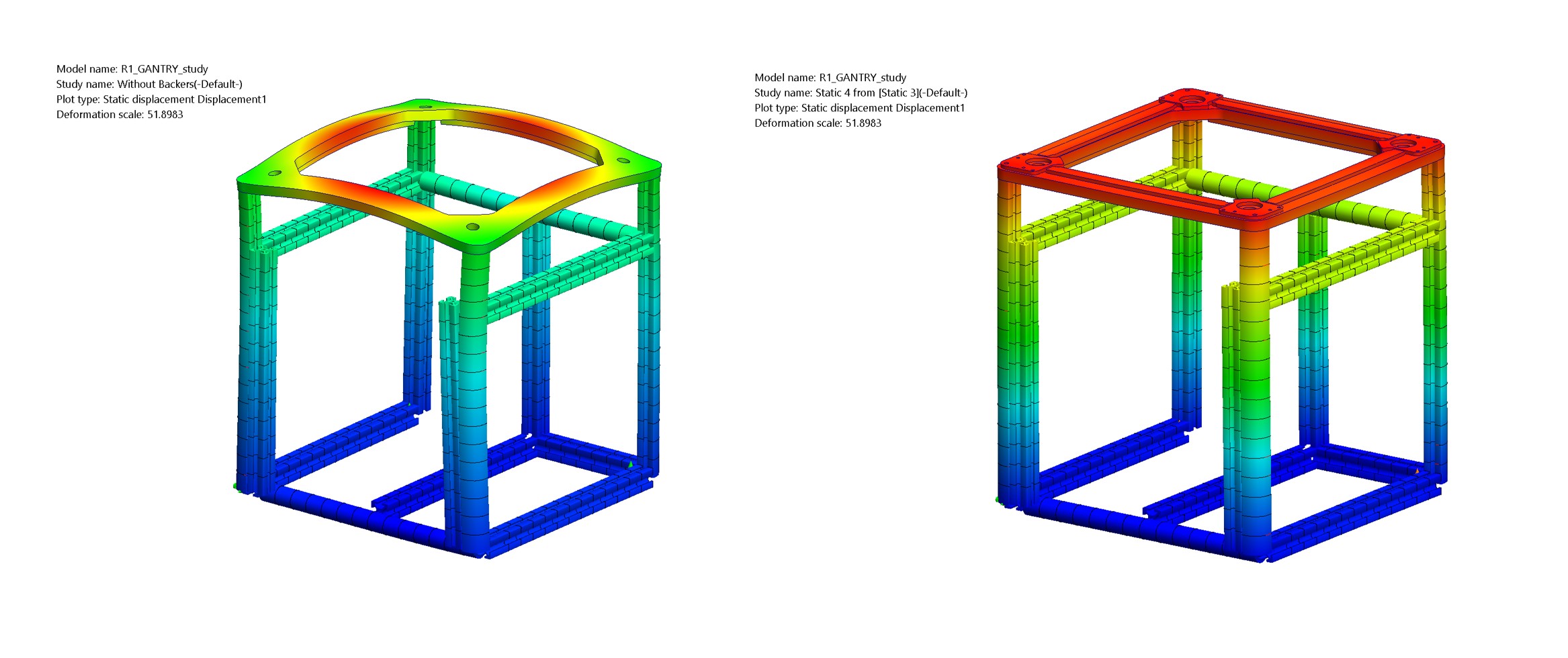

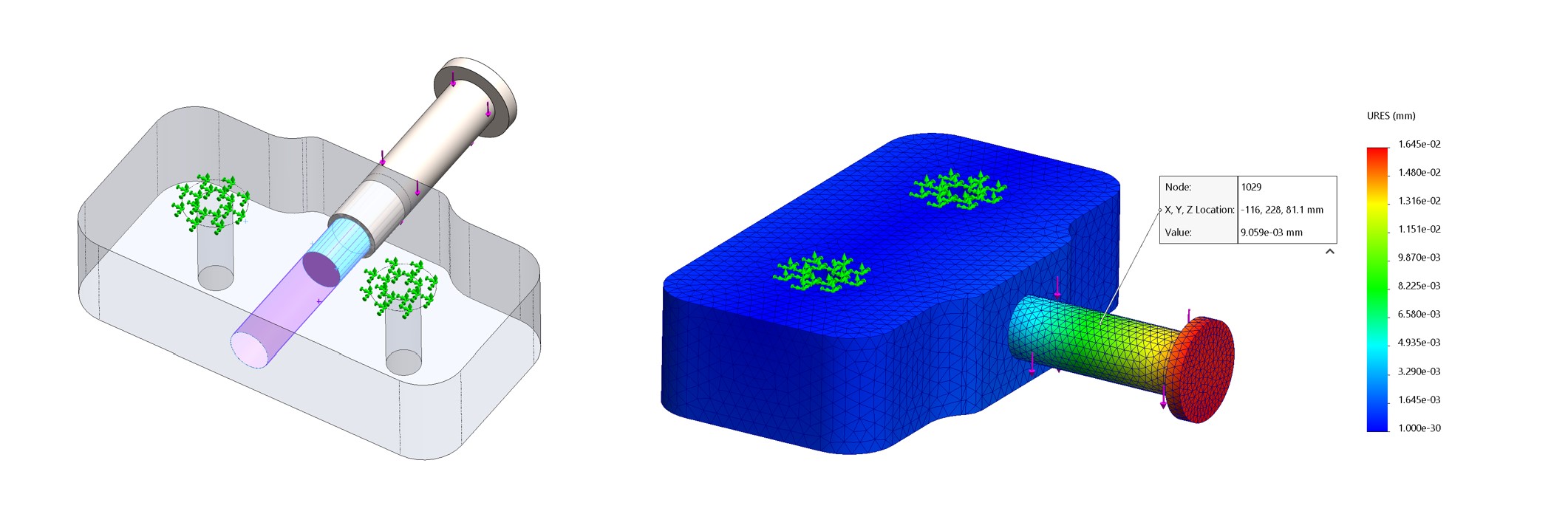

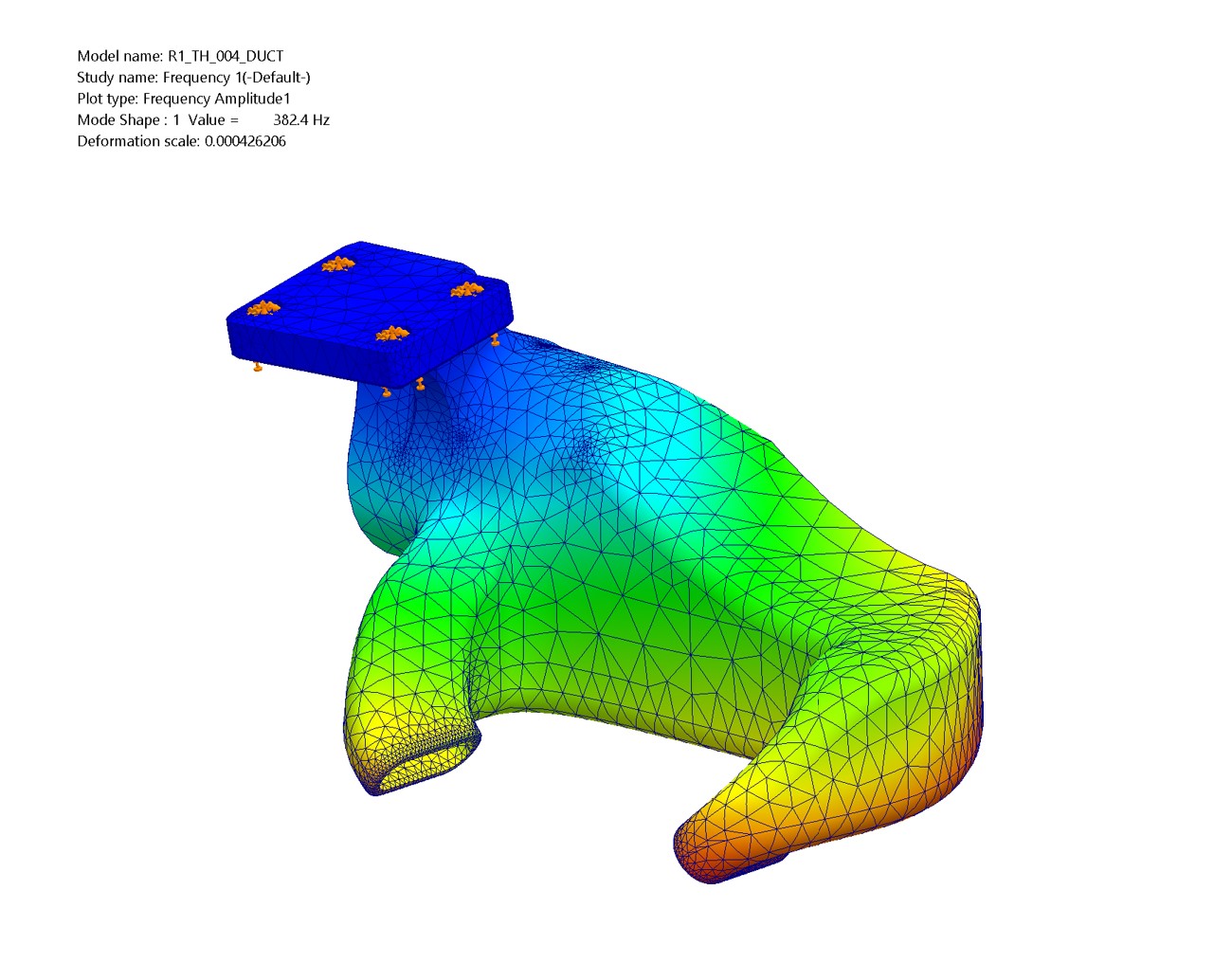

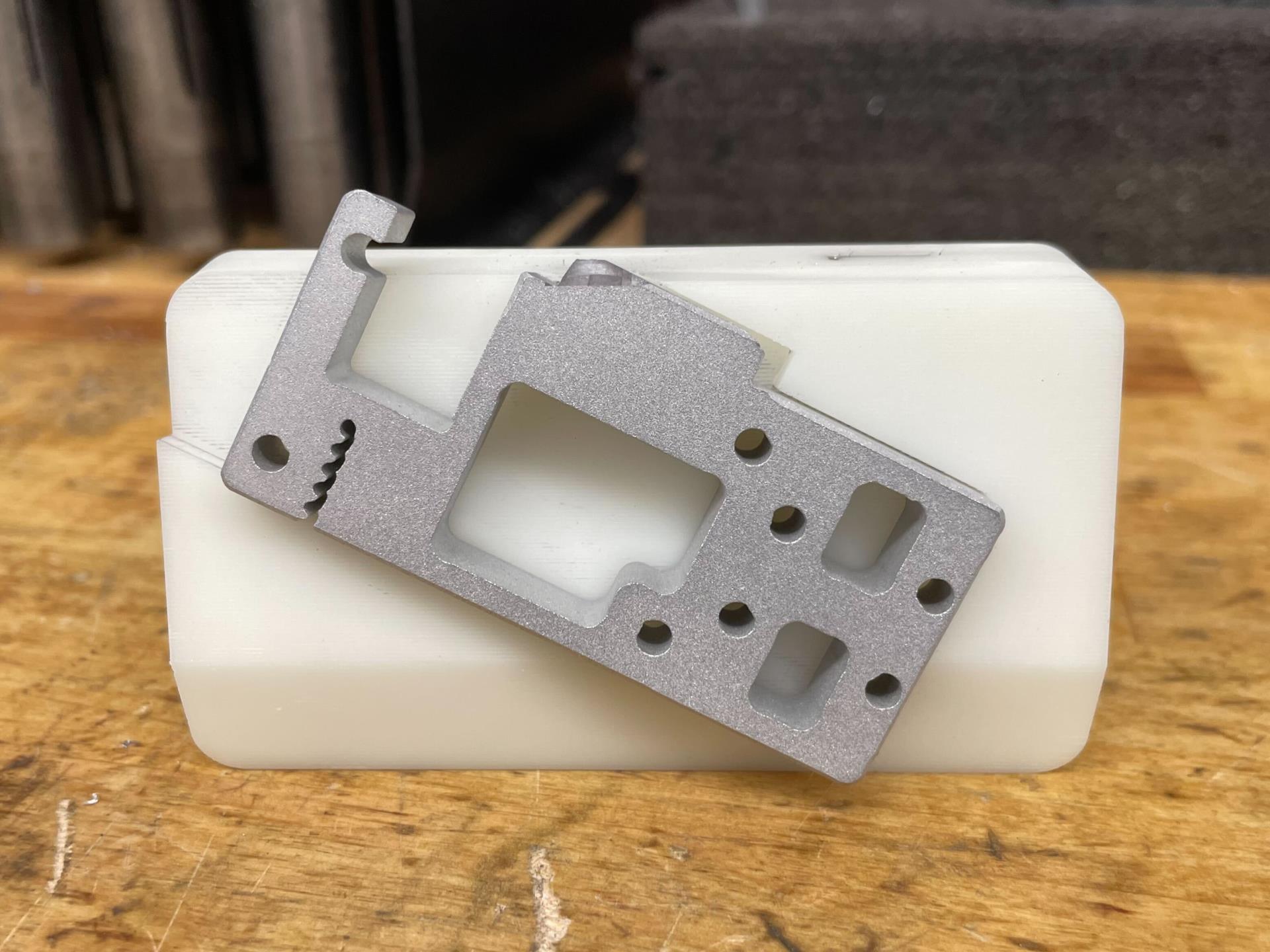

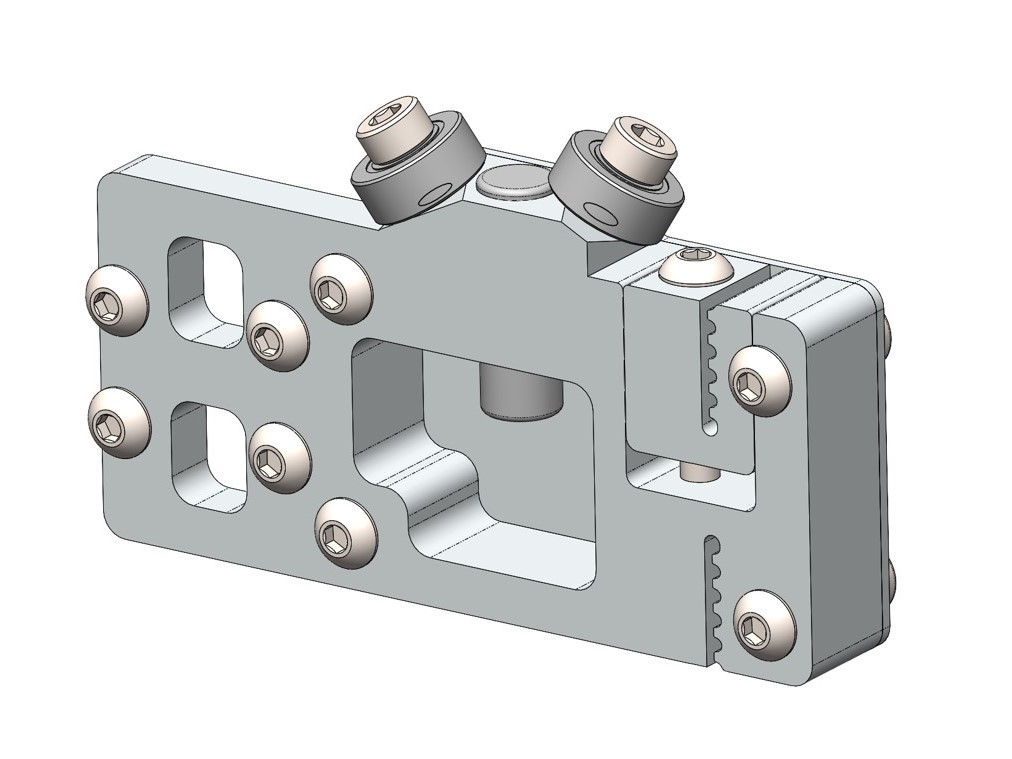

The main structure is designed around a cast aluminum tooling plate to which the gantry linear rails are mounted.

Steel reinforcements are used to compensate for bi-metallic deformation of the plate under the anticipated thermal loads.

I used FEA to optimize the geometry of the members to improve flatness by an order of magnitude.

The main structure is designed around a cast aluminum tooling plate to which the gantry linear rails are mounted.

Steel reinforcements are used to compensate for bi-metallic deformation of the plate under the anticipated thermal loads.

I used FEA to optimize the geometry of the members to improve flatness by an order of magnitude.

A full-featured avionics suit developed for high-power model rockets

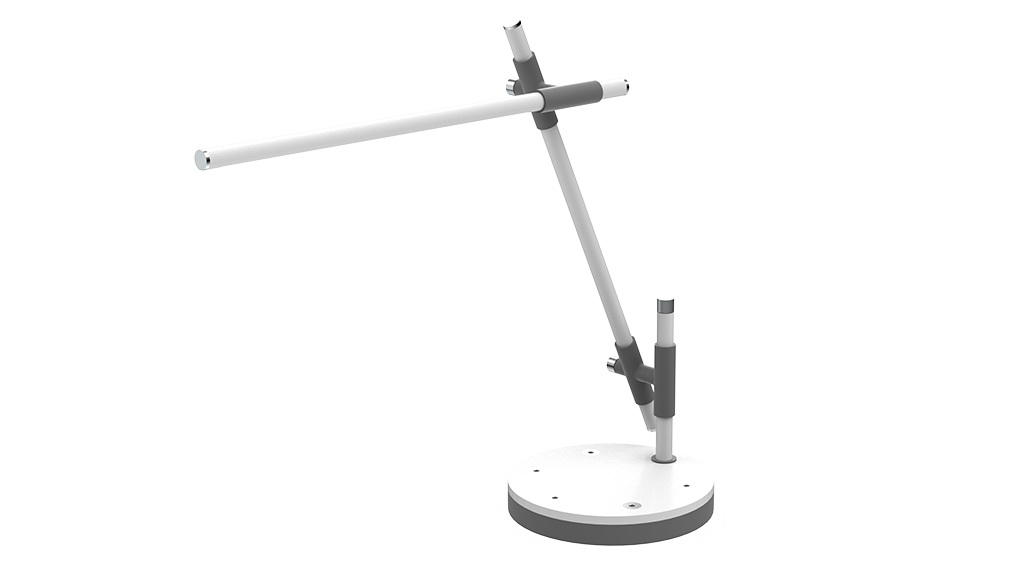

A custom dimable LED desk light

Meet my fleet of self-built multirotors